uPVC Pipes

Unplasticized Poly Vinyl Chloride (uPVC) also known as rigid PVC, is one of the most versatile and sustainable materials used in the construction industry. The extra materials give uPVC superior resistance to chemical erosion, and its smooth inner walls allow water to flow more smoothly with less turbulence. uPVC is also resistant to a wider range of temperatures than PVC.

- The Standard length of pipe is 6 meters or as required

- Pipe with one solvent cement socket or plain end

- Pipe color is white or grey

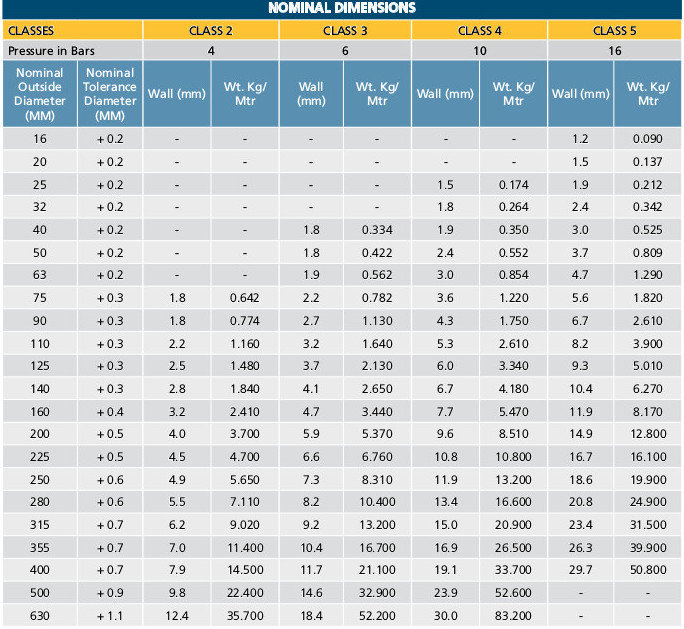

Dimensions based on DIN 8062 & SASO 14

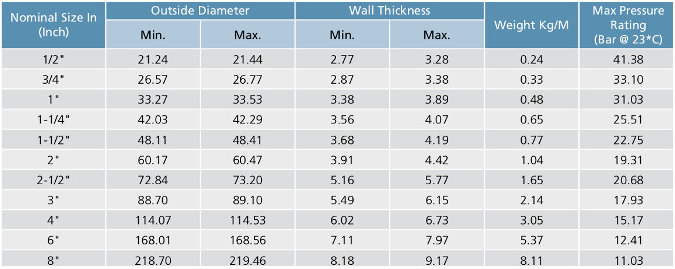

Dimensions based on ASTM D1785 Schedule 40

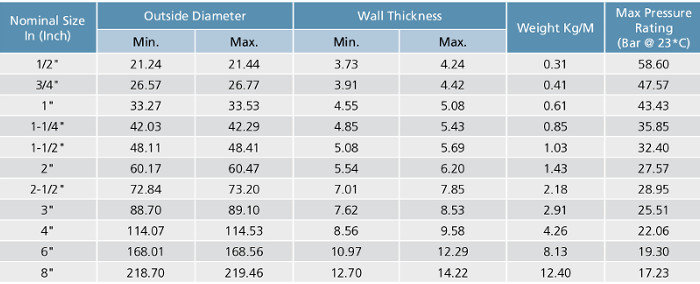

Dimensions based on ASTM D1785 Schedule 80

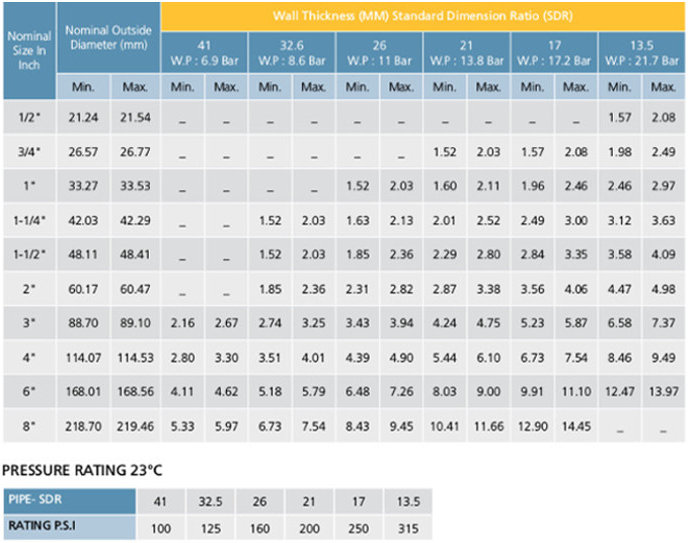

Standard Dimension Ration (SDR) UPVC Pipes according to ASTM D 2241