HDPE Pipes

High Density Poly Ethylene (HDPE) pipes are suitable for high pressure applications, mostly underground and is often used to replace ageing concrete or steel mains pipelines. The toughness and resistance to chemicals of polyethylene, as well as the corrosion resistance and low weight have helped HDPE in cost-effective and durable fluid and gas piping systems.

Al Tamam HDPE pipes are manufactured from virgin raw materials in state of the art manufacturing facilities. The plant is fully integrated with a Quality Control Laboratory carrying stringent raw material and finished goods tests for achieving and maintaining uncompromising quality, consistency & matching the specification as laid down in various International Standards.

Advantages

All Al Tamam piping products are made using PE 100 grade high density polyethylene, which offers many advantages over alternative piping material like PVC ductile iron, steel, clay and GRP.

In addition to its flexibility and ease of installation, HDPE pipes have longer life expectancy than traditional materials and exhibit high performance across various applications.

Benefits

- Zero leaks

- Corrosion and chemical resistant

- Lower life cycle costs than traditional pipe materials

- Lightweight and flexible

- Impact resistant

- UV protection

- Environmental friendly

- Well-suited for trenchless applications

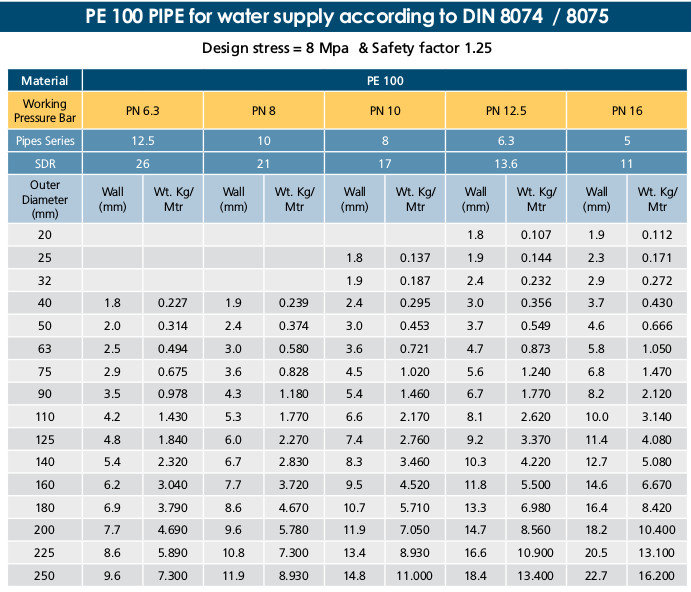

HDPE Pipe Outer Diameter from 20 mm to 400 mm. Pipe length 12 M FROM OD 110 - 250 MM & FROM OD 20-110MM COIL UPTO 100 METER

Black colour with blue extruded stripes for potable water and Black Sewage or Cable Duct or any colour upon request.